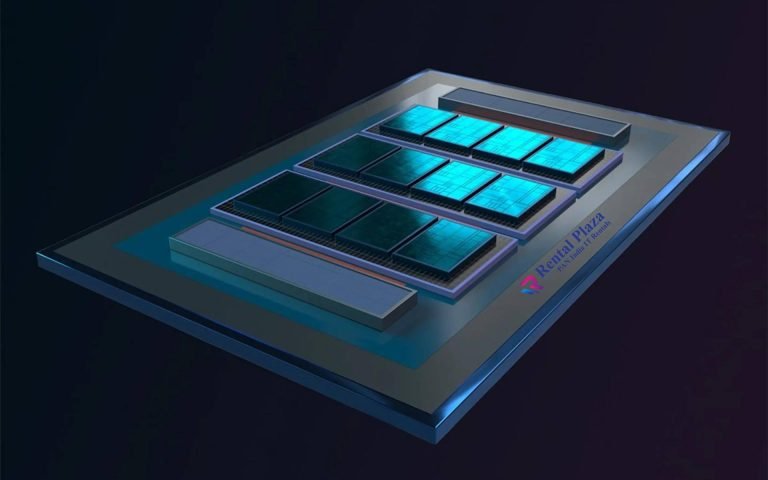

In the fast-paced world of semiconductor innovation, Intel has once again positioned itself at the forefront with its revolutionary 18A process technology. This breakthrough marks a significant leap forward in chip design, introducing two groundbreaking innovations: backside power delivery and nanosheet transistors, also known as RibbonFET. These advancements promise to enhance performance, efficiency, and scalability in ways previously thought impossible, paving the way for the next generation of computing devices. In this blog, we’ll explore the details of Intel’s 18A technology, the implications of backside power delivery and nanosheet transistors, and how these innovations are setting new benchmarks in the semiconductor industry.

The Evolution of Chip Design: Enter the 18A Process

The semiconductor industry has long been driven by the need to pack more transistors onto a chip, a trend famously described by Moore’s Law. However, as we approach the physical limits of silicon, further miniaturization has become increasingly challenging. Intel’s 18A process technology, with its 18 angstrom (1.8 nanometers) feature size, represents a bold response to these challenges. The 18A process not only continues the trend of shrinking transistor dimensions but also introduces entirely new architectures and power management techniques that redefine what is possible in chip design.

Nanosheet Transistors (RibbonFET): Redefining Transistor Architecture

One of the most significant innovations in Intel’s 18A technology is the introduction of nanosheet transistors, or RibbonFET. This new transistor architecture departs from the traditional FinFET design, which has been the industry standard for the past decade.

Understanding RibbonFET

RibbonFET, or nanosheet transistors, are built with a gate-all-around (GAA) architecture, which provides superior control over the flow of electricity within the transistor. Unlike FinFETs, which use a fin-like structure rising from the silicon wafer, RibbonFETs utilize horizontal nanosheets that are stacked on top of each other. These nanosheets are surrounded by the gate on all sides, allowing for more precise control over the transistor’s on/off state.

Advantages of RibbonFET

The RibbonFET design offers several critical advantages over traditional FinFETs:

- Enhanced Electrostatic Control: The GAA architecture improves the gate’s ability to control the transistor’s channel, reducing leakage currents and enhancing overall efficiency.

- Greater Scalability: RibbonFETs can be scaled down more effectively than FinFETs, allowing for continued increases in transistor density and performance as feature sizes shrink.

- Customizability: The width of the nanosheets in a RibbonFET can be varied, providing designers with the flexibility to optimize the transistors for either higher performance or lower power consumption, depending on the application.

- Improved Power Efficiency: With better control over the transistor’s behavior, RibbonFETs deliver superior performance per watt, making them ideal for both high-performance computing and mobile devices where energy efficiency is critical.

Backside Power Delivery: A Revolutionary Power Management Innovation

The second major innovation in Intel’s 18A process is backside power delivery. This new approach to power management fundamentally changes how power is distributed within a chip, offering significant improvements in both performance and efficiency.

The Need for Backside Power Delivery

In traditional chip designs, power and signal interconnects are located on the front side of the silicon wafer. As transistors have become smaller and more densely packed, this arrangement has led to increased resistance, voltage drops, and signal interference. These issues can degrade performance, particularly in high-power, high-performance applications.

How Backside Power Delivery Works

Backside power delivery solves these problems by relocating the power interconnects to the backside of the silicon wafer. By separating the power and signal interconnects onto different layers, backside power delivery reduces the resistance and voltage drops associated with power distribution, while also minimizing interference with signal pathways.

Benefits of Backside Power Delivery

- Improved Power Efficiency: By reducing resistance and voltage drops, backside power delivery ensures that power is delivered more efficiently to the transistors, leading to lower overall power consumption.

- Enhanced Performance: With power interconnects located closer to the transistors, signal integrity is improved, allowing for faster and more reliable operation.

- Increased Density of Signal Interconnects: By moving power interconnects to the backside, more space is available on the front side for signal interconnects, enabling higher transistor density and better performance.

- Better Thermal Management: Backside power delivery also facilitates improved heat dissipation, which is crucial for maintaining performance and reliability in high-power chips.

The First Chips to Utilize 18A Technology

Intel’s 18A process technology is set to be used in a new generation of chips that will power everything from high-performance data centers to consumer devices. These chips will be the first to integrate both backside power delivery and RibbonFET nanosheet transistors, offering unprecedented levels of performance, efficiency, and scalability.

Applications of 18A Technology

The advanced capabilities of the 18A process make it ideal for a wide range of applications, including:

- Data Centers: The improved power efficiency and performance of 18A technology will be crucial for powering the next generation of data center processors, which require immense computational power and energy efficiency.

- Artificial Intelligence: AI workloads demand high levels of parallel processing power and efficiency. The 18A process will enable AI accelerators with greater performance per watt, helping to drive advancements in machine learning and neural networks.

- Mobile Devices: With its focus on power efficiency, the 18A process will also be key to developing next-generation mobile devices that offer longer battery life and enhanced performance.

Conclusion: A New Era in Semiconductor Innovation

Intel’s 18A process technology represents a monumental step forward in semiconductor innovation. By introducing nanosheet transistors and backside power delivery, Intel is addressing some of the most pressing challenges in chip design today. These innovations not only enable higher performance and efficiency but also set the stage for continued advancements in computing technology.

As the first chips utilizing 18A technology begin to roll out, the impact on the semiconductor industry will be profound. From data centers to mobile devices, the 18A process is poised to drive the next wave of innovation, delivering the computing power needed to meet the demands of tomorrow’s applications. Intel’s commitment to pushing the boundaries of what is possible ensures that the future of chip design is brighter than ever.